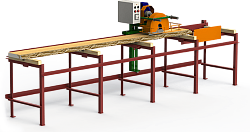

The disk, edge-cutting, two-saw machine Altai-011

Altai-011 machines are two-edged edge-cutting machines with quick-set sizes between saws designed for sawing (longitudinal cutting) of unedged boards and slabs in order to obtain edged sawn timber (edged boards, slats, whetstones, three-edged croaker), and ensures reliable operation even with round-the-clock loading. Its design meets all safety requirements.. This machine has high productivity due to symmetrical cutting from two sides in one pass. The size between the saws is set by turning the handle on the operator's side. Saws converge and diverge symmetrically about the longitudinal axis of the table.Maximum size between saws - 600 mm!

Principle of operation:

The board is laid in the centre of the table and cut off immediately on both sides when the saw carriage moves in both forward and reverse directions. The board clip is provided with pinch rollers in the centre of the board. Circular saws rotate against each other, always in the same direction, including when changing the direction of the saw block. The saw block is moved manually by the machine operator behind the handrails.

For ease of transportation, the frame (table) of the machine is disassembled into two guide sections (3.89 m each) and five racks.

The scheme of the machine:

| Parameters | Value | ||

| Installed engine power, kW | 5,5x2 pcs. | ||

| Supply network (current type), V |

380 (3 phase) |

||

|

The maximum width of the board, mm - storage - received |

600 552 |

||

| Maximum board thickness, mm | to 100 | ||

|

Diameter of circular saws, mm -external - landing |

450 50 |

||

| Workpiece basing | on the table plane along the longitudinal center + clamp with 2 rollers | ||

| Overall dimensions of the machine, mm (LxBxH) | 7800x1400x2000 | ||

| Machine weight, kg | 420 | ||

| Productivity, m3 per shift | to 20 | ||

Recommended products

Edge former Altai-007 single-saw, gasoline and electric

Edge former Altai-007 single-saw, gasoline and electric

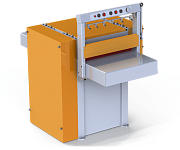

Single-shaft multisaw machine Altay KS-500

Single-shaft multisaw machine Altay KS-500

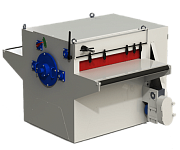

Single-shaft multisaw machine Tank KS1000

Single-shaft multisaw machine Tank KS1000

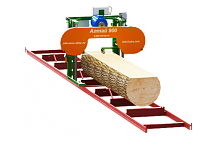

Horizontal power-saw benches horizontal Altai gasoline and electric

Horizontal power-saw benches horizontal Altai gasoline and electric